I’ve been so busy with work and diving into the garage, I haven’t actually taken the time to update the site and share Buttercups news with you all. As I managed to arrive early at the station today, I have a rare short breather, and so I’m using this time to write an update.

Firstly, she is running great, and sounding fab, if possibly a little bit loud. For the SVA she was allowed upto 101db, something she achieved when she passed, although as you may remember she failed the first time with 102db!

Exhaust

The exhaust I have made using a combination of new parts from Jetex and the old down pipe, with some ‘adequate’ welding that I’ll need to revisit and tidy up. The exhaust presently exits straight out through the chassis, but as I get closer to refitting the body, this will be angled down and out in the normal location.

Turbo

All of the turbo air plumbing has been installed although a number of components need to be fixed in place and I am still missing a number of hose pipe clamps. One of the oil feeds into the top of the turbo was leaking, and upon inspection was missing the gasket. A few pounds spent at the Audi garage, problem solved. I have installed the stock blow off valve but it’s currently venting to the open air, and this is less than optimum as the spring is not strong enough to keep it shut when at idle and this lets extra air come in which in turn weakens the air/fuel mix and makes her run like a dog! I’ll have a new silicone t-piece from ASH hoses soon and solve that, along with a cone air filter.

Oil

The oil cooler is installed, and I’ve changed the filter and the oil. A few oil leaks existed, but these are all now solved and I can run her up to operating temperature. The oil filter head has a thermostat that only brings the oil cooler in to play once the oil has warmed up sufficiently. As with the majority of components in the right wing pod I still need to create all the fittings and brackets to hold things in place.

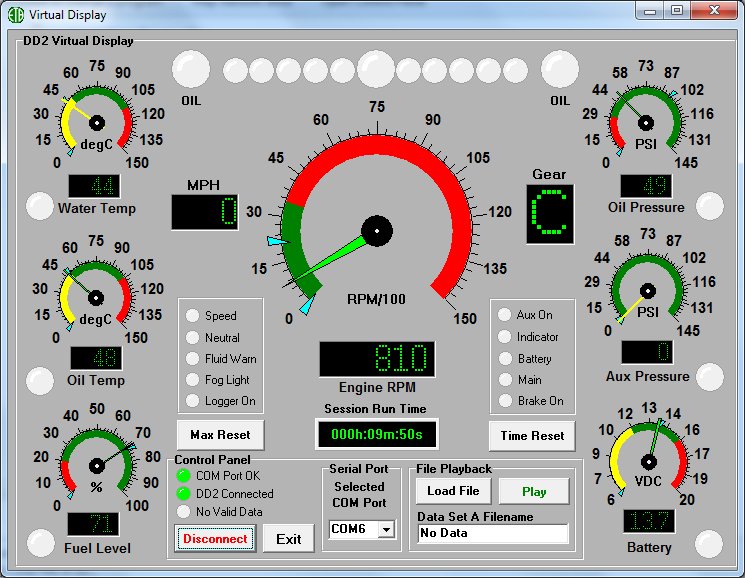

Dashboard

The Digidash2 from ETB is installed, and I have managed to get the engine sensors all installed and working. It took a fair amount of time to work out which sensors were required for the ECU or run on fan relay and which I could remove to make room for the new sensors. The resistance characteristics for the existing sensors were not the same as the DigiDash2 sensors so they all needed replacing. I had hoped to replace the stock oil temperature sender that is housed in the oil pump, but on removal this appears to also support the oil pressure control ball and spring, so a new location had to be found. The standard audi block has two oil pressure senders in two separate galleries, one is the 0.3 bar and the other one the 1.9 bar. The upper of those two was replaced by the DigiDash2 combi sender, and I replaced the 0.3 sender with the DigiDash2 oil temperature sender, inserted into an adapter from EuropaSpares.

Last night I went around and started organising the wiring loom, or rather what’s left of it. I have 6 wires leading to the ECU or the engine loom that are not connected to anything, once the original use for this is ascertained I can remove them and then start finalising the loom layout. I want to avoid too many connections in the loom as these are all potential failure points.

The next steps I have, that I can think of at the minute, are:

- Radiator fan relays

- Lighting controls (Arduino)

- Wiring loom wrap up

- Heat shielding around loom and chassis near turbo/exhaust

- Clean up exhaust welds

- Finish exhaust pipe

- Modify roll cage to fit around plenum

- Fit throttle cable correctly

- Add handbrake cable support

- …and probably a whole lot more!